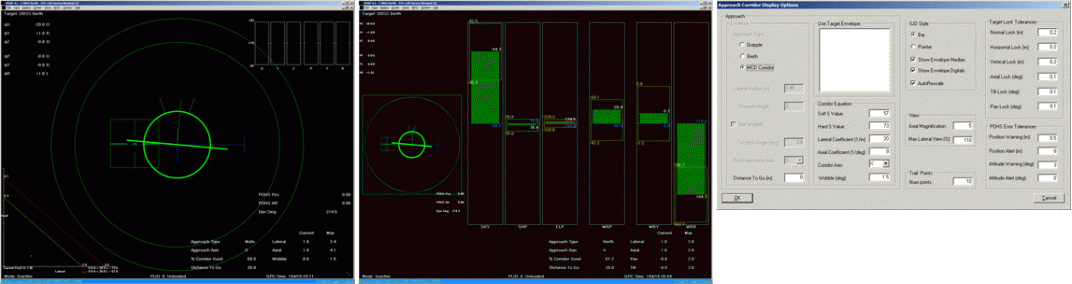

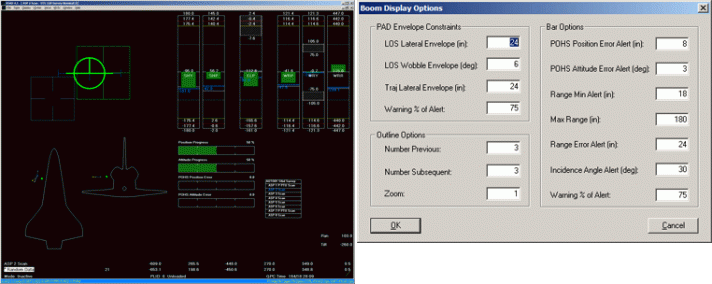

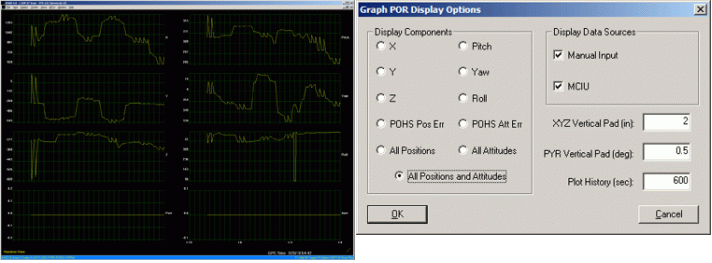

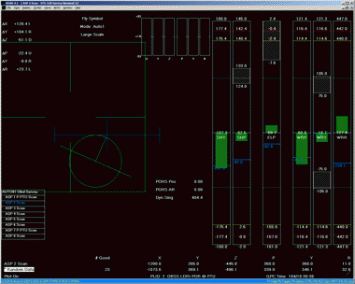

RMS Situational Awareness Display (RSAD)

The Robotics Situational Awareness Display (RSAD) is a Windows based application developed specifically for NASA. RSAD provides visual steering cues and other robotics information during robotic arm operations both during training and during real-time, inflight operations. Versions of RSAD are in use on both the Space Shuttle and International Space Station programs, running on both the IBM Thinkpad 760E and A31p platforms that support the two programs. RSAD integrates data from multiple sources (telemetry, the manipulator controller interface unit (MCIU), space vision system (SVS), then merges and processes it for display to give astronauts different tools that will help him/her to have a good idea of what’s going on with the arm. This training device has decreased the number of training hours needed and saved NASA considerable money for each flight. RSAD provides multiple displays, both general purpose and task specific.

Benefits:

- Inflight Performance & Safety

Both crew performance and safety are enhanced during robotic operations because of the intuitive graphical view of data beyond that provided by the flight software displays and because crew members see an integrated, big picture of the activity, not just the individual task. - User Satisfaction

Since development is end-user driven and iterative, users define and identify features that they need and want. - More Efficient Training

During training, RSAD allows for a wide view of the situation to allow the crew to more easily determine activities of significance as they refine their approach to accomplishing mission objectives. - Reconfigurability

Both mission data and user preferences are data reconfigurable allowing for fast and efficient updates and customization. - Captured Data

All input data is recorded and may be used to drive the RSAD displays in playback mode or for post-processing. - Ease of Operation

RSAD operations are highly automated for hands off operation during flight. - Robustness

Full error detection on external interfaces and file I/O to immediately detect, isolate, and identify problems. - Graceful Degradation

RSAD makes the best use of available data to drive the displays in the event of external interface errors. RSAD also reduces the display update rate as the processor becomes saturated.

Why is it Innovative or Significant?

RSAD provides an intuitive graphical view of data beyond that provided by the flight software displays. Development is user driven with the astronaut office (CB) providing the requirements and user interface guidelines. A spiral development process allows iterative refinement of the requirements and user interface, based on crew experience in flight and during training.

RSAD provides the users with a unique integrated view by merging data from multiple data sources at 2 Hz. Although specifically targeting the flight laptop environments, RSAD will run under Windows 95 or later with at least a Pentium III processor. A robust architecture supports the addition of both displays and external interfaces. The architecture provides a general solution to the task of providing multiple displays driven by multiple data sources.

Sample Displays